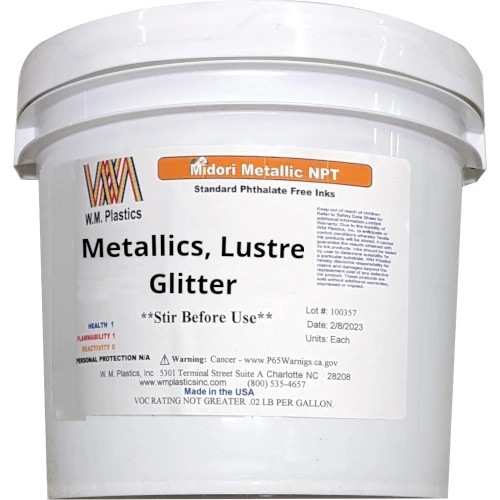

Product Description

These inks are designed to stand out on garments by providing a unique appearance that will catch anyone’s eye. Available in an array of colors and contains great opacity to cover the dark garments.

Black, colored or white garments. Cotton/Polyester, Acrylic & Polyester garments (with LB underlay)

Crystalina is made of an iridescent translucent mylar flake that is suspended in a clear plastisol base. The clear base has a much lower loading of flakes so there is a greater amount of clear base. This allows the under color to show through when this ink is overprinted. Crystalina is also known as “Shimmer” and “Yellow Sparkle.” Because of the nature of the flake, it gives the overprinted color a shiny, sparkly, rich look. Crystalina is very similar to glitter.

- Bleed Resistance: None

- Opacity: High

- Storage: Ideally 65 to 80 F. Keep out of direct sunlight.

- Mesh: 86

- Stencil: Any direct emulsion or capillary film.

- Wet on Wet Printing: Can be printed wet-on-wet to increase production.

- Modifications: To reduce viscosity use Curable Reducer (I10-9906), improve stretch use G&S Base (I10-1020), puff use Puff Additive (I10-9903), extend color use Soft-hand Base (I10-0111) & for suede puff or dulling use Suede Additive (I10-9907).

- Squeegee Hardness & Angle: Medium to hard at a 45 degree angle.

- Fusion/Curing:325 F/163 C for 1 to 1 ½ minutes. Oven temperature can be increased and dwell time decreased. For heat presses use 390 F/195 C for 8 seconds. Because metallics and lustres reflect it may be necessary to increase temperature and dwell time.

- Wash-up: Any plastisol cleaner.

- Special Notes: PVC inks are thermoplastic compounds that require heat to fuse or cure. If ink rubs off on a white cloth or cracks, temperature and/or dwell time should be increased. Do not dry clean and always test on fabric to be printed.