Product Description

M&R’s DS-4000 Digital Squeegee is setting the standard for hybrid printing. At production rates of 400+ prints per hour the DS-4000 bridges the gap between direct-to-garment (DTG) printing and screen printing. Since the Digital Squeegee prints on top of a screen-printed underbase a wide array of fabrics - including synthetic and performance blends - can now be printed digitally, opening the door to new market trends and cost-effective high-end digital textile imaging.

Using a screen printed underbase eliminates the need for time-consuming pretreatment, and expensive digital white underbase inks. M&R’s hybrid printing process reduces the time, labor, and cost required by digitally printing alone, making small and mid-size print runs cost effective.

An eight-to-twelve-color screen print would typically require hours to perform separations, process and expose screens, mix inks, and register the press. The same screen print can be set up and printed on the Digital Squeegee in a fraction of the time with a minimal number of screens, greatly reducing art times that are normally associated with multi-color screen print jobs.

Hybrid prints can be embellished with specialty printing effects before or after the digital print, expanding creative possibilities by blending the best attributes of screen printing with the ease and detail of digital imaging.

With some creative planning, a common screen-printed white underbase can be used with varying digital print data to produce completely different images in the same print run.

Digital Squeegee inks can be cured in conventional gas dryers, such as the Sprint® 3000, Sprint 3000 D, and Sprint 3000 DHZ.

CONTROL CENTER

DESIGN & CONSTRUCTION

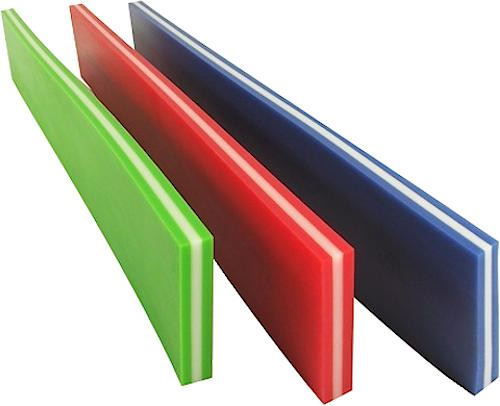

FABRIC COMPATIBILITY

HIGH-SPEED PRINTHEADS

INK COMPATIBILITY

INK SYSTEM

PRESS COMPATIBILITY

PRINT AREA

RESOLUTION

WARRANTY, SERVICE AND SUPPORT

Z-AXIS ADJUSTMENT

OPTIONS:

WARRANTY, SERVICE AND SUPPORT