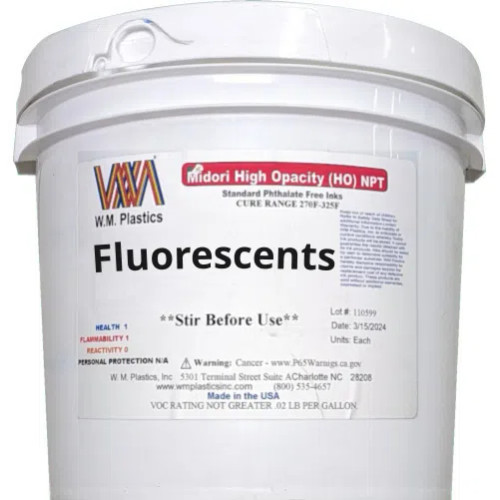

Product Description

WM Plastics High Opacity (HO) Series Non-Phthalate Plastisol Inks (Midori Series)

High Opacity (HO) inks are formulated to be directly printed onto medium to dark colored, 100% cotton garments. These inks provide great coverage and have a creamy body.

- For Cotton/Polyester blends, Acrylic, & Polyester garments, use with low-bleed underlay

- Can be printed wet-on-wet to increase production

- Low Buildup

- Easily releases from the screen

- Very soft hand

Additives:

- To reduce viscosity use Curable Reducer (I10-9906)

- Improve stretch use G&S base (I10-1020)

- Extend color use Just-So-Soft Base (I10-1044) or Soft-Hand Base (I10-0111)

- Puff use Puff Additive (I10-9903)

- For suede or dulling use Suede Additive (I10-9907)

Mesh: 86-240 (34 to 110 threads per cm)

Stencil: Any direct emulsion or capillary film.

Squeegee: Sharp, Medium to hard, at a 45 degree angle.

Flashing: 700F for 9 seconds, just enough for the surface to be tack free.

Fusion/Curing: 325F/163C for 1 to 1 ½ minutes. Oven temperature can be increased and dwell time decreased.

Heat Presses: 390F/195C for 8 seconds.

Bleed Resistance: None

Storage: Ideally 65F to 80F. Keep out of direct sunlight.

Wash-up: Any plastisol cleaner.

Special Note: PVC inks are thermoplastic compounds that require heat to fuse or cure. If ink rubs off on a white cloth or cracks, temperature and/or dwell time should be increased.

Do not dry clean and always test on fabric to be printed.